Analysis

Summary

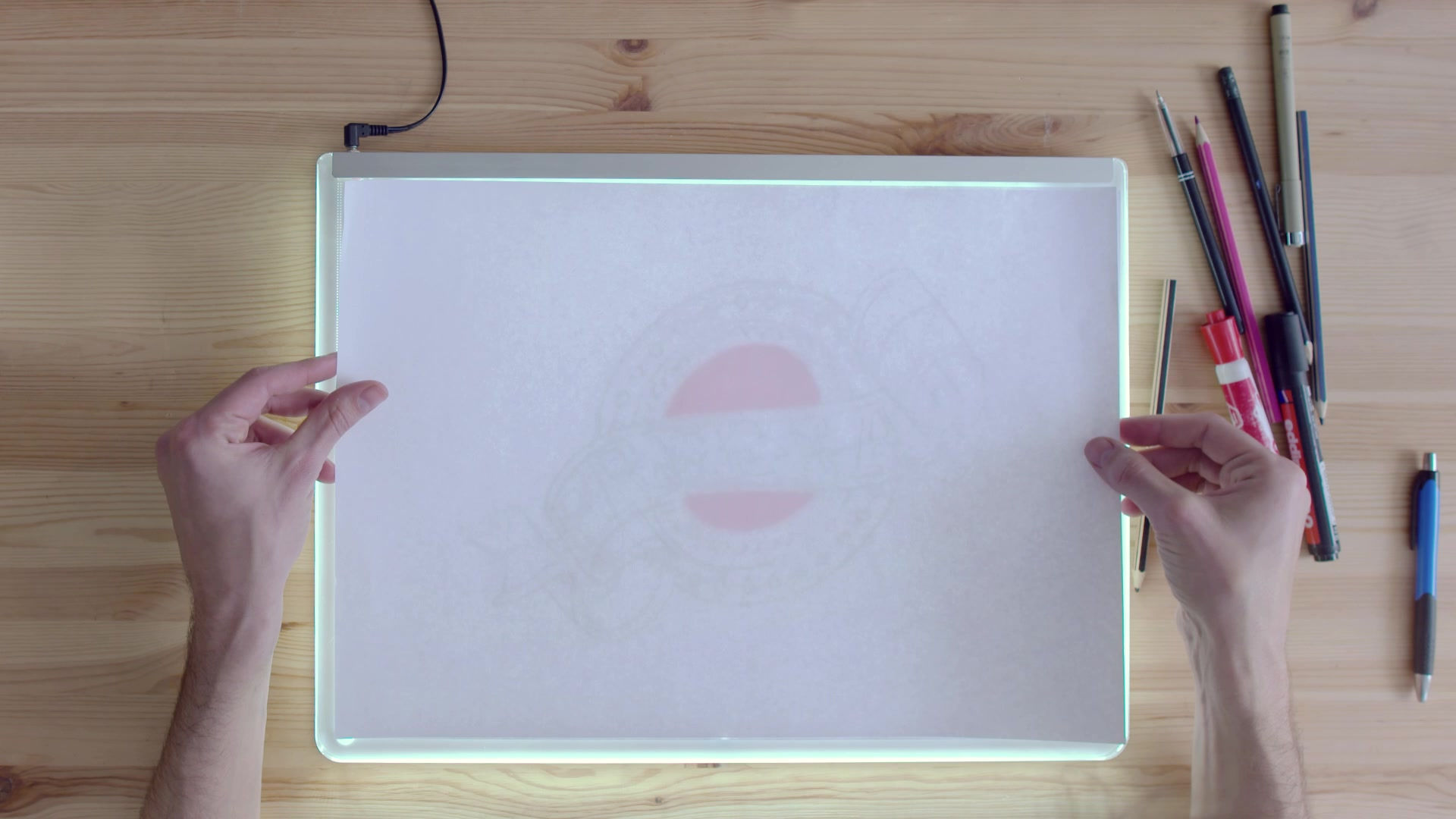

This project was used green sheet and SoildWorks model to analyze the requirements, which were panel needs to perpendicular to incoming sunlight with 2 degrees deviation, a steel frame to install 22.25 inches*12.57 inches solar panel, increased 20% energy flue in the surface from incoming sunlight, and both axes must be animated.

Analysis Details

Since The main operation of solar tracker is to rotate in vertical direction.

Based on the original calculation, the motor was strong enough to drive the solar panel since it was only required 32.2 lb*in torque and the motor can support the maximum of 46 lb*in torque.

However

As the next green sheets shown, the gear that used for 2L004 motor and 1.25’’ shaft was changed to 1:3 gear, compare to original design and calculated that 1:1 gear was enough to drive the shaft to rotate in vertical direction.

The change was due to the wrong weight that used to calculate the torque because the original calculate only contained the weight of solar panel. However, the total weight has to be the weight of the whole top parts which including solar panel, 1.25’’ shaft, two side supports, two plastic supports, and two wood beams.

Therefore, the total weight was 36 lb. instead of 6.61 lb. for solar panel only. Since the gear ratio changed, it required a large size of gears that was not fit inside the back space of solar panel, so the gear had to locate outside the frame.